Production Process

Lathe Machining

Inner ring and outer ring

The machined bearing rings are identical to the finished product and facilitate the grinding process later on.

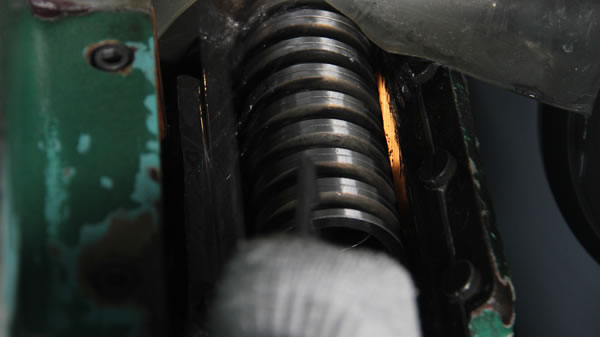

Bearing Cage

As one of the four major components of ball bearings, the bearing cage is used to secure and balance the ball in the bearing raceway. Our bearing case is made of hybrid laminate, nylon, copper, and silver plated materials. The picture below shows the machining of a bakelite made bearing cage, which is light weight and helps ensure a high speed rotation.

Heat Treatment

The entire heat treatment process takes 2 hours. This treatment allows the bearing parts to achieve the required hardness by changing their internal structure.

Grinding Process

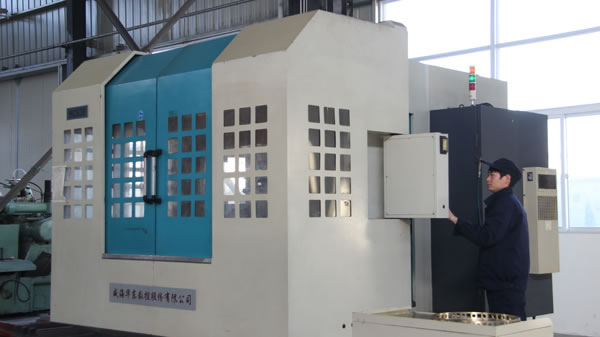

In the processing and production of precision bearings, we have upgraded more than 100 sets of traditional hydraulic processing equipment using CNC technology and have also purchased automatic production equipment, including the following:

Double disk grinder: This requires only a single person to operate and is used in the first step of grinding to achieve a fine polishing on two parallel surfaces of the bearing. The high speed double disk grinder polishes vertically and corrects parallel errors.

High precision centerless grinding machine: This machine requires two operators and is used to polish the outer ring of the bearings. We have several high precision centerless grinding machines to meet the processing requirements of industrial bearings with different sizes.

Precision lapping machine for bearing raceway: The lapping effect directly determines the precision, height and service life of the bearings. Because of that, we carry out continuous monitoring throughout the lapping process, and the bearings that pass visual inspection are sent to the testing room for a spot check.

4-axis machining center: This machine is equipped with a tool magazine and is used to manufacture bearings with a large diameter.

CNC grinding machine: The CNC grinding machine is an important piece of automatic equipment used for grinding precision bearings. A single trained operator can handle 4 to 5 of them simultaneously, saving labor costs.

CNC machining center: This automatic production equipment assists in carrying our mass production.

Strict detection processes are carried out throughout the entire process of grinding, effectively preventing defective products from entering the next stage.

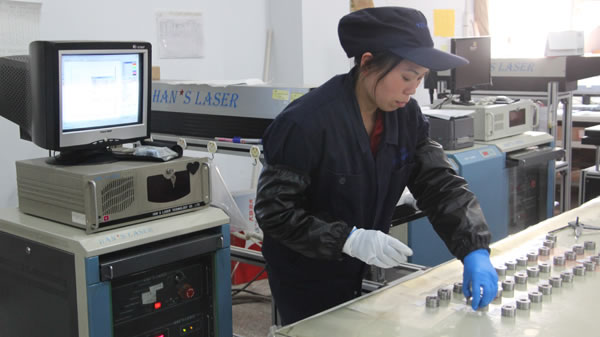

Marking: We have three marking machines used to mark the company logo, production date, model number and more on the bearing products. The picture below shows the marking of matching lines.

Washing: The bearing parts and assembled finished products both need to be washed and cleaned. We have four cleaning lines, each of which is controlled by two operators.

Assembly: Workers select the bearing parts that have the dimensions and clearances that conform to required standards and sort them for assembly.

Packaging: After washing, the finished products are dried using the drying equipment installed on the cleaning lines. After undergoing corrosion protection, bagging, vacuuming, certification attachment, boxing, and security trademark application, the finished products are packed according to industry standards.